SKS helps optimise your processes with energy-efficient pumps

Pumps are essential in a wide variety of industries and processes, varying from water supplies to food production. Like the beating heart of processes, they move matter from A to B. To produce foodstuffs or pharmaceutical substances, various hygienic pumps are used, which ensure a general movement of product or facilitate evaporation, high pressure, priming and CIP return tasks. Depending on the application and the product flowing through the pump, we can recommend the right type of pump for you, such as a centrifugal, twin screw or positive displacement pump.

Optimal processes

Pumps account for 10 to 20% of the total worldwide energy use and the demand for pump capacity is increasing more and more. At the same time, we are under increasing pressure to save energy and reduce our ecological footprint. Efficient, energy saving pumps are therefore a must. Energy-efficient pumps make the entire production process smoother (and consequently more economical). This results in fewer faults and you end up saving energy and therefore money, a win-win solution in other words. A pump can be set up locally in such a way that it does its job as best and effectively as possible. And you get the most out of a minimum amount of energy!

Energy-efficient LKH centrifugal pumps

Less energy wasted through vibration, noise and heat: up to 50% more efficient. Long service life and not prone to failure. Greater energy efficiency of the entire production process..

Inoxpa DIN-FOOD pump

High capacity (up to 1000 m³/h) and yet energy-efficient. Wide and flexible use in the food, and chemical industries

DuraCirc Circumferential piston pumps

Perfect balance between reliability, durability, high efficiency and hygienic performance. The all-stainless steel DuraCirc has a wide performance range, making it applicable in any process.

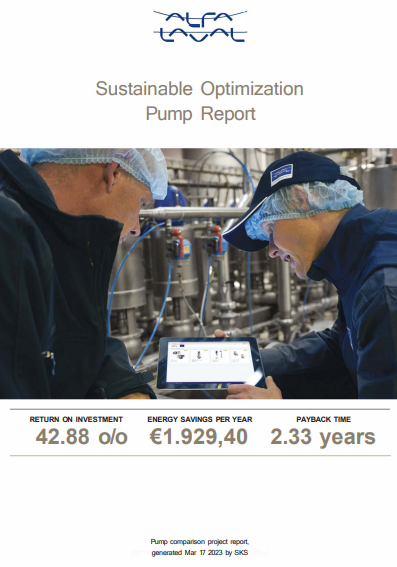

Measure your equipment!

Keep a close eye on the condition of your pumps with Alfa Laval's condition monitor. This solution proactively provides you with up-to-date information on pump status. A benchmark with basic data puts you in control.