SKS optimises heat transfer and energy efficiency

At SKS, we believe in the power of sustainability. Our Alfa Laval plate heat exchangers are designed not only to improve heat transfer, but also to optimise energy efficiency. With our advanced technologies, you can make your processes more efficient, improve performance while saving energy and minimising environmental impact.

Take, for example, our Alfa Laval Hygienic line, specially developed for hygienic applications in the pharmaceutical, food and beverage industries. These premium plate heat exchangers not only take process hygiene to the next level, but also reduce the environmental footprint by reducing energy, water and detergent consumption.

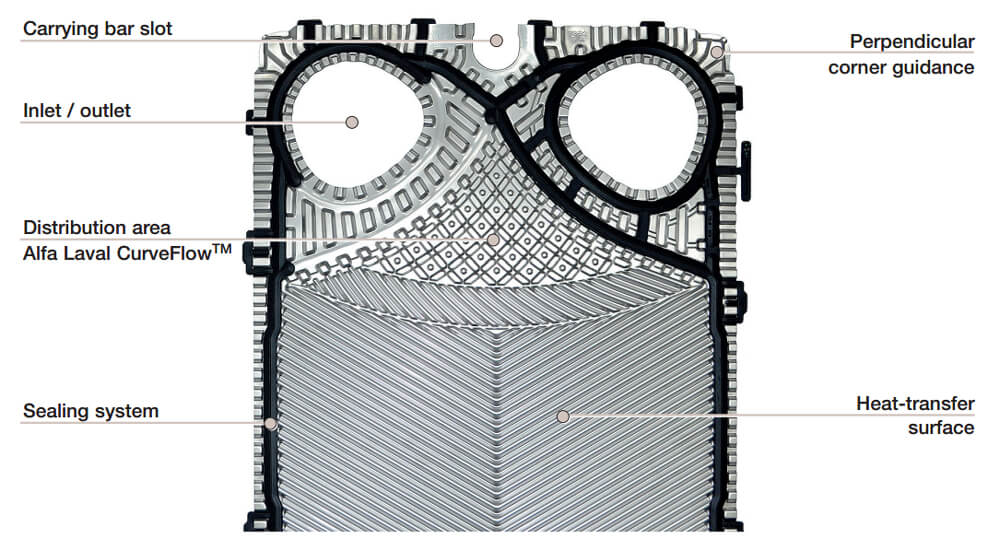

Alfa Laval CurveFlowTM

A new innovation in plate heat exchangers

The Alfa Laval CurveFlowTM features a new distribution area design. This ensures superior flow distribution and greater pressure drop over the main heat transfer area and provides several benefits:

- A more compact heat exchanger: fewer plates are needed.

- Increased energy efficiency: better flow distribution reduces the risk of fouling build-up, reducing the need for more pumping power to compensate for greater pressure loss.

- Lower maintenance costs: because fewer plates are needed, they are quicker to clean and there are fewer costs for spare parts.

The new design ensures optimum distribution of the medium across the entire plate width. In doing so, the cross-wave pattern between the distribution surface and the main heat transfer area ensures improved heat transfer. Unlike a traditional plate design, it is possible to use thinner plates at high pressure. The overall improvement in heat transfer efficiency is up to 15%.

Higher throughput

Thanks to the non-round ports, the port area in the board is larger than in a conventional circular design. This creates a higher power capacity at the same speed, enabling higher utilisation.

Up to 40% improvement in self-cleaning capacity

The new design gives the media up to 20% higher velocity at the end of the plate width. This improves shear stress over the heat transfer area by up to 40%, minimising the risk of contamination at the most critical part of the plate.

Alfa Laval Hygienic Line

Key features

- Developed for the most hygienic application with a focus on gentle handling of sensitive products.

- Specially developed to reduce the consumption of energy, water and detergent.

- Optimised power distribution and smoother plate pattern for up to 15% better energy efficiency and up to 10% lower pressure drop.

- On average 10% less steel used than previous models during production for lower CO2 emissions.

Choose sustainability with the Alfa Laval Hygienic line

Alfa Laval's Hygienic line takes process hygiene and product safety to the next level and optimises energy efficiency. This premium range of plate heat exchangers is specially developed for hygienic applications. It raises the bar on hygiene while reducing the environmental footprint, by reducing the use of energy, water and cleaning agents, among other things. The line is specially designed for the pharmaceutical, food and beverage and other industries where excellent hygiene and efficiency are paramount.

Sustainable results

Optimised power distribution and a smoother plate pattern improve heat transfer efficiency, improving energy efficiency by up to 15%. These features also help reduce the pressure drop by up to 10%, while allowing the heat exchanger to perform the same task. By using on average 10% less steel in manufacturing the unit compared to previous models, carbon dioxide (CO2) emissions in the product are similarly reduced. And anyway, efficient cleaning can lead to lower consumption of water, chemicals and energy.

Hygienic heating and cooling for maximum product safety, uptime and energy efficiency:

- Improved product safety thanks to unique design features on plates and gaskets.

- Superior cleanability thanks to innovative plate pattern for improved hygiene and optimal power distribution.

- Special plate pattern for gentle handling of delicate products.

- Longer run times between cleaning cycles thanks to optimised media distribution.

- SmoothPort for an even and therefore cleaner inlet surface and a smooth outlet for maximum drainability.

- High heat transfer efficiency, minimising the use of energy and materials.

- Simple maintenance with easy access and ClipGripTM gasket attachment.

Need more information?

Contact us for more information on this standard.

We can also give you technical advice on the different products with this standard.