M&S systems

M&S product recovery system Pigging Technology

The M&S pigging system encompasses all fittings and components required for the construction of a piggable process line. Depending on the product and/or process, components from the BASE//LINE program can be supplemented with fittings from the PRO//LINE and HY//LINE segments.

- Full exploitation of the production without any losses

- Small batches without losses

- Quick product change

- No mixing phases

- Less numbers of pipelines (reduced investment costs)

- Avoiding of sediments in pipeline

- Up to 90% less use of cleanising media

- Longer cleaning agent service life

- Lower degree of waste water contamination

- Increase in efficacy

- Short payback periods

BASE//LINE M&S Product Recovery System

Single way and shuttle systems for simple application such as meat, confectionery or baked goods, drink and tobacco, etc.

PRO//LINE

Single way and shuttle systems as CIP/SIP capable models for foodstuffs such as dough, meat emulsion, dairy products, cosmetics and special fibrous or bulky products.

HY//LINE

As inline station for single way and shuttle systems in CIP/SIP execution, pig permanent in product flow, for beverages, foodstuffs and cosmetics.

Pigging Stations and Components:

- Sizes DN 25 to DN 150

- Materials AISI 316L, further materials upon request

- VMQ (silicone) seals, EPDM, HNBR and FKM(all FDA conform)

- VMQ (silicone) pigs (FDA conform) with 2 encapsuled high-performance magnets

- Stations operated manually, pneumatic or driven by electric motors

- Stations in CIP/SIP execution

- Complete prefabricated and pretested units

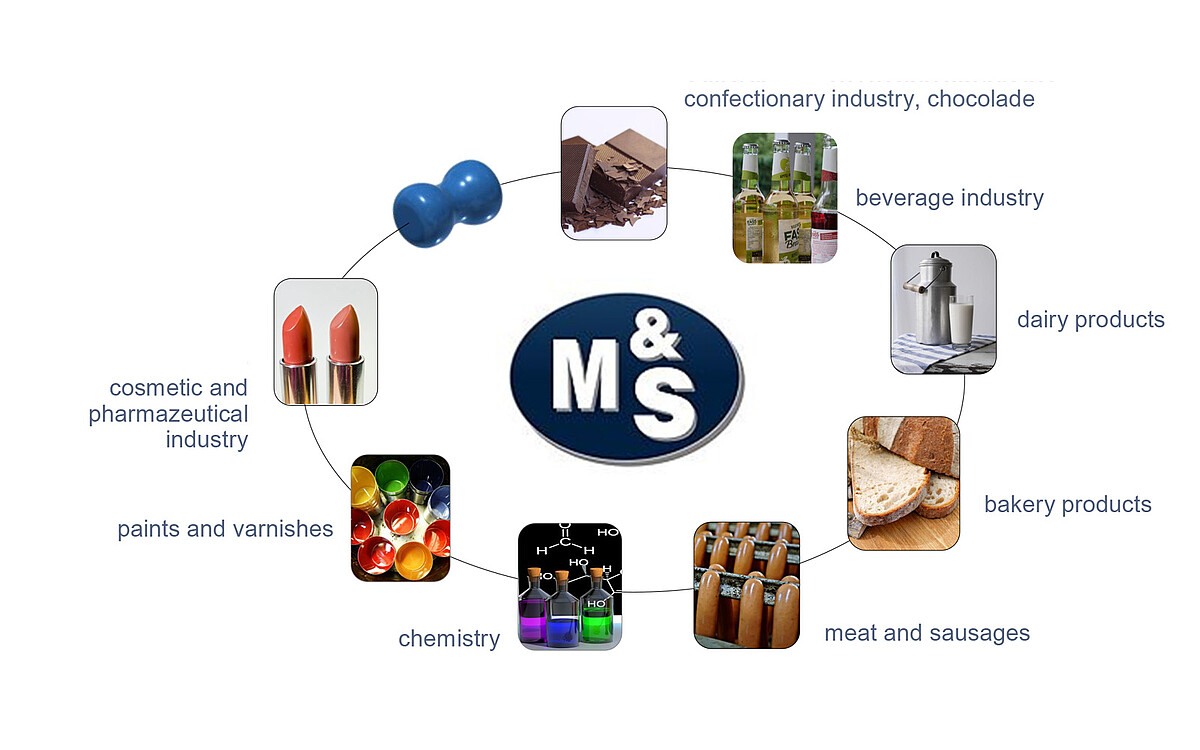

Fields of application

|

We like to think along with you!Would you like more information or advice about Pigging Recovery Systems? Please complete the online form for a consultation.  |