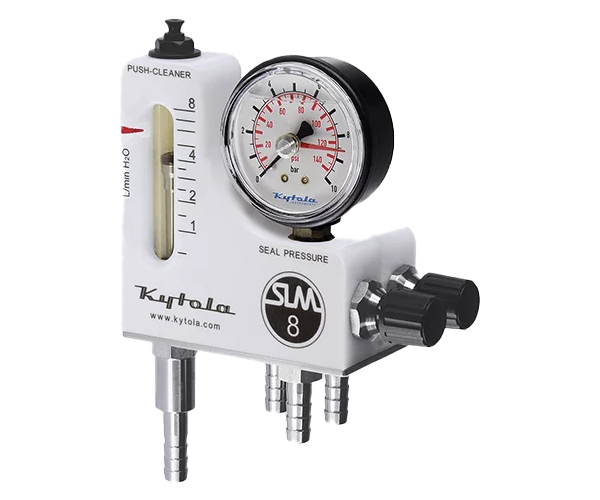

The Kytola SLM Seal water flow meter

The Kytola SLM seal water flow meter ensures optimal liquid flow to protect your seals effectively. Offering the convenience of on-the-go cleaning and servicing without disrupting your operations, the SLM is a reliable solution for various equipment such as pumps, agitators, refiners, and screens with shaft seals.

In industrial settings, maintaining a consistent flow of sealing water is crucial for the proper functioning of seals. Seal water serves multiple purposes including cooling, lubricating, and preventing the entry of process media into the seal chamber. Monitoring the flow and pressure of seal water is essential for assessing seal condition and preventing costly issues.

Kytola's commitment to efficiency and quality is evident in the SLM seal water flow meter, which not only delivers top-notch performance but also helps in cost and resource savings. By accurately controlling water flow and pressure, significant reductions in water and energy consumption can be achieved.

Designed specifically for applications requiring uninterrupted seal water flow, the SLM features a robust and compact design resistant to external impact. Equipped with a clog-resistant flow control valve and optimized for use with contaminated water, the SLM ensures reliable operation even in demanding environments.

With its built-in cleaner and compatibility with all seal types, the SLM offers unmatched versatility and ease of use. Additionally, the option to integrate an inductive proximity sensor for alarm output further enhances its utility and safety features.

Kytola's commitment to efficiency and quality is evident in the SLM seal water flow meter, which not only delivers top-notch performance but also helps in cost and resource savings. By accurately controlling water flow and pressure, significant reductions in water and energy consumption can be achieved.

Designed specifically for applications requiring uninterrupted seal water flow, the SLM features a robust and compact design resistant to external impact. Equipped with a clog-resistant flow control valve and optimized for use with contaminated water, the SLM ensures reliable operation even in demanding environments.

With its built-in cleaner and compatibility with all seal types, the SLM offers unmatched versatility and ease of use. Additionally, the option to integrate an inductive proximity sensor for alarm output further enhances its utility and safety features.

The Kytola SLM is used in following applications:

Ö Double mechanical seals

Ö Gland packings

Ö Flush water

Ö Purging

Ö Other flow measurement

Main technical features:

Ö Clog resistant flow control valve

Ö Mounting bracket

Ö Solid construction

Ö Reduced seal maintenance

Ö Built-in cleaner does not interfere with operation

Ö Excellent corrosion and heat resistance

Ö All models alarm-ready

Ö Clear metering scale

Ö Hose barb connectors

Ö Alternative connectors on request

Technical data

| Model | SLM |

| Body | POM (PVDF optional material, code “K”) |

| Flowtube | PSU with standard POM body (optional borosilicate glass tube, code “L”) or borosilicate glass tube with PVDF body, material code “K” (optional PSU tube, code “KM”) |

| Metallic parts | AISI 316, float AISI 329 |

| O-ring seals | Viton® |

| Connectors | 3/8″ (10 mm) hose barb connectors |

| Max. pressure | 20 bar |

| Max. temperature | 100°C |

| Weight | 1.2 kg (incl. package, pressure gauge, pressurizing valve) |