Hygienic Line heat exchangers

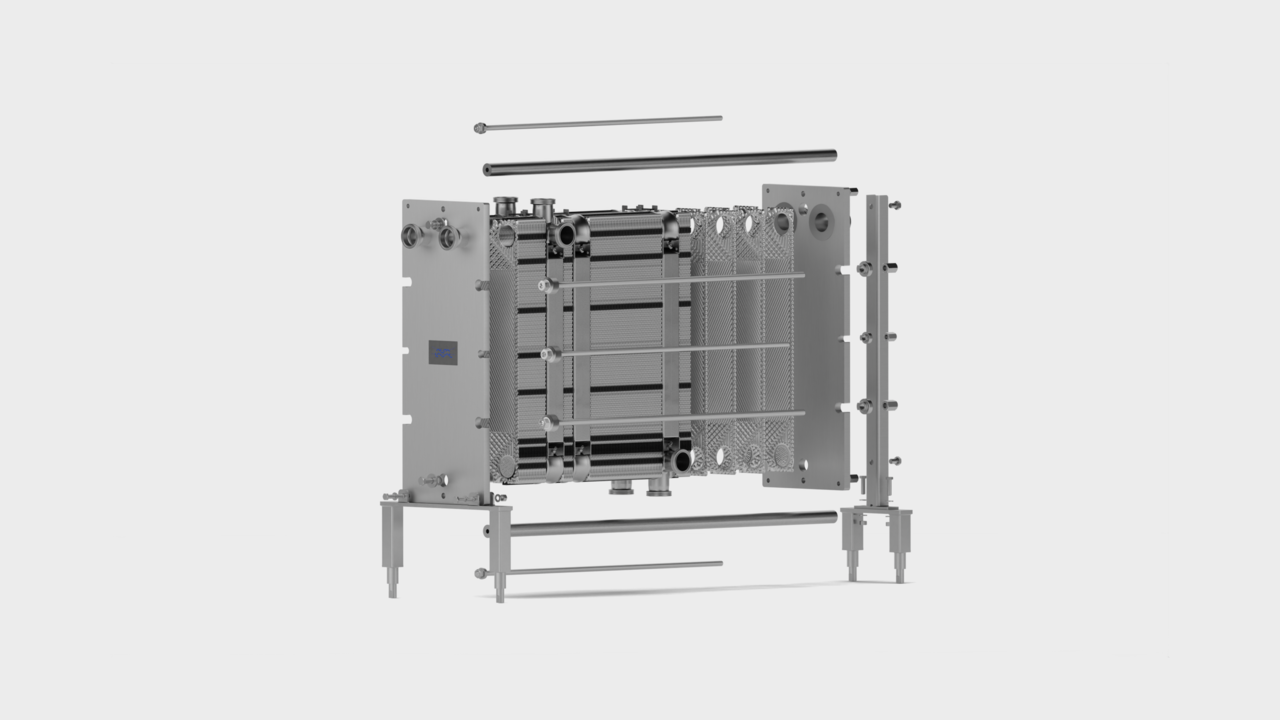

The Hygienic Line by Alfa Laval elevates process hygiene and product safety. This premium range of plate heat exchangers is specifically designed for hygienic applications in the food, beverage, and pharmaceutical industries. With optimised flow distribution and a smoother plate pattern, heat transfer is improved and energy efficiency can increase by up to 15%. At the same time, pressure drop is reduced by up to 10%, without compromising performance.

These energy-efficient and sustainable plate heat exchangers contribute to reducing the ecological footprint. On average, 10% less steel is used compared to previous models, resulting in lower CO₂ emissions during production. The Hygienic Line is not only a smart choice for process optimisation, but also for sustainable production environments that demand the highest standards in hygiene and efficiency.

Main features

- Developed for the most hygienic application, with a focus on the soft handling of sensitive products.

- Specifically developed to reduce the use of energy, water and cleaning agent.

- Optimised current distribution and a smoother plate pattern for an increase of up to 15% in energy efficiency and a decrease of up to 10% in the pressure drop.

- On average a reduction of 10% in steel consumption compared to previous models during production, resulting in lower CO2 emissions.

Advantages

- Improved product safety because of unique design features on plates and gaskets.

- Can be cleaned perfectly because of an innovative plate pattern for even better hygiene.

- Longer intervals between cleaning cycles thanks to optimised media distribution.

- Minimum consumption of energy and materials, owing to high heat transfer efficiency

- Simple maintenance with easy access and ClipGripTM gasket mounting.

- Accelerates your journey towards sustainability thanks to high energy efficiency.

- Increased uptime, increased productivity.

- Hygienic heating and cooling for maximum product safety.

Features

Hygienic WideGap

Discover the Hygienic WideGap plate heat exchanger from Alfa Laval Hygienic line. Engineered to handle fluids with fibers and particles, this advanced technology delivers exceptional energy savings and heat recovery, outperforming conventional shell and tube heat exchangers. Perfect for food processing, the hygienic WideGap accommodates a variety of products, including pulp-filled juices, purées, crushed tomatoes, dressings, and plant-based beverages.

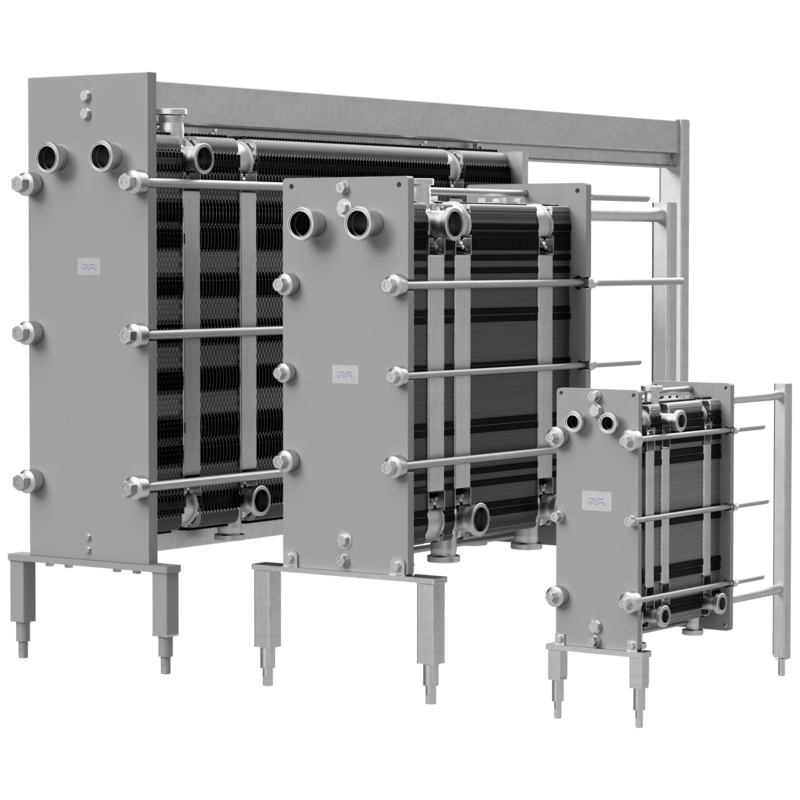

SKS and gasket plate heat exchangers

Our engineers look at the right solution together with your process data. With a total range of exchangers including tubular heat exchangers, gasket plate exchangers and scraped heat exchangers, they are always able to provide tailor-made advice. With Hygienic Line products, you are assured of hygienic heating and cooling for maximum product safety, uptime and energy efficiency.

More information?Would you like more information or advice about Alfa Laval Hygienic Line? Please complete the online form for a consultation.  |

The streamlined SmoothPortTM prevents interruptions in the product flow and maximises the possibility for cleaning and disposal.

The streamlined SmoothPortTM prevents interruptions in the product flow and maximises the possibility for cleaning and disposal.  EquiflowTM optimises the media flow, for uniform heat treatment with minimal pollution.

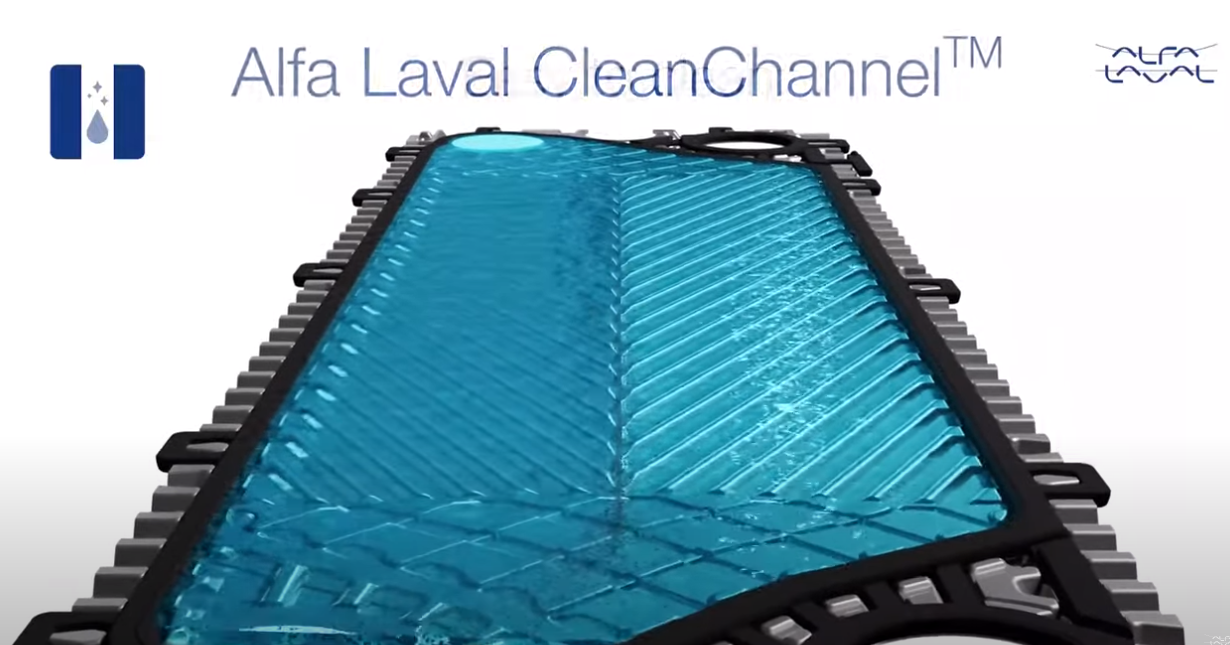

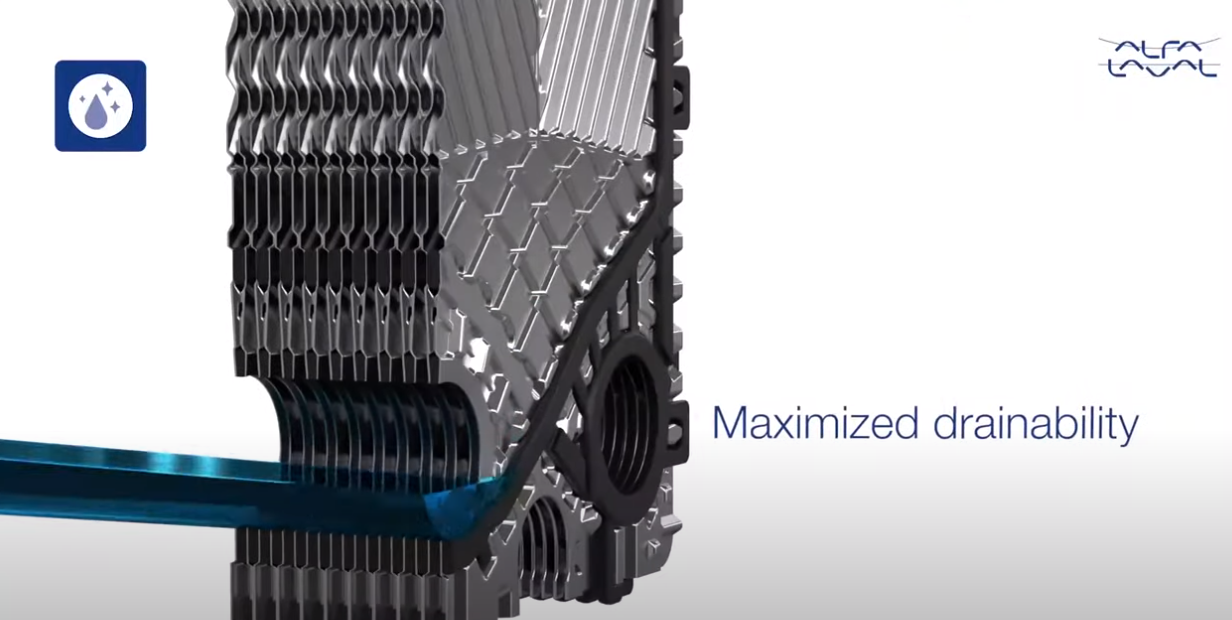

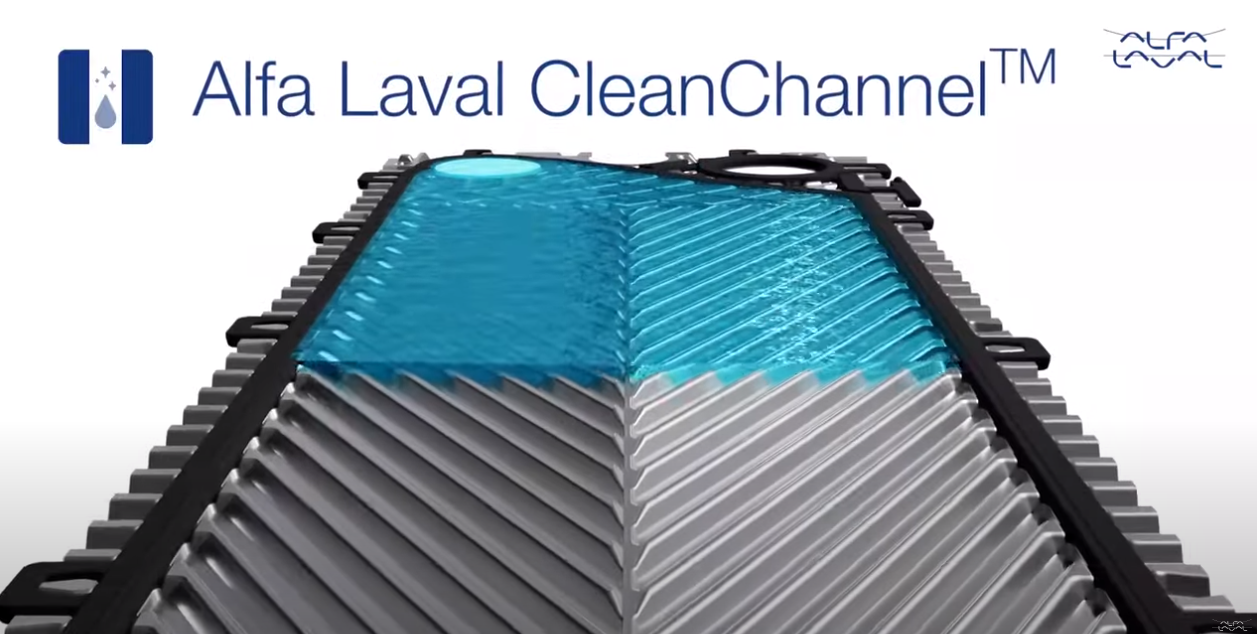

EquiflowTM optimises the media flow, for uniform heat treatment with minimal pollution.  CleanChannelTM ensures easy removal of particles during cleaning, to guarantee the highest hygiene standards.

CleanChannelTM ensures easy removal of particles during cleaning, to guarantee the highest hygiene standards.