Integrity test

What is an integrity test?

An Alfa Laval integrity test is a specific service for gasketed plate heat exchangers. This test gives you detailed insight into the condition of the plates and gaskets, allowing you to better plan maintenance, maintain control over your production process and ensure product safety. This proactive approach ensures that your equipment remains reliable.How does an integrity test work?

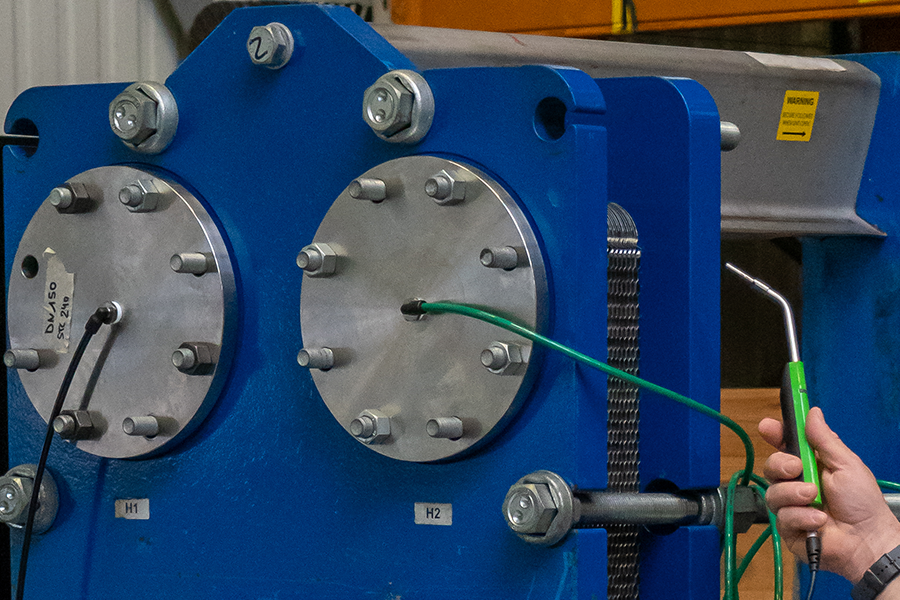

Our integrity tests offer exceptionally high accuracy and safety. This involves pumping a non-toxic, non-flammable mixture of hydrogen and nitrogen through the heat exchanger. This makes even the smallest cracks, corrosion or other signs of wear visible. The advanced sensors detect any gas leaks and accurately identify the nature of the problem, such as micro-cracks, corrosion or a weakened gasket.

The methodology behind the integrity test

The integrity test was developed with a focus on accuracy, safety, speed and durability.-

Accuracy

The combination of hydrogen and nitrogen is ideal for inspecting heat exchangers thanks to its rapid diffusion and ability to detect minuscule defects, even cracks that do not yet allow liquid to pass through. This mixture disappears quickly from the atmosphere and reduces the likelihood of false results compared with other gases such as helium. Moreover, our automated system minimises the risk of user error. - Safety

The hydrogen mix used is non-flammable (certified according to ISO 10156) and non-toxic. It does not corrode plates and gaskets and is approved for use in the food industry. - Speed

The test is quick and easy, with no need to open the plate pack. By simply connecting a gas pump, results can be viewed after only 15 minutes. No additional cleaning or follow-up operations are required, making the test also suitable for hard-to-reach units. - Durability

Unlike helium, which is scarce and non-renewable, hydrogen and nitrogen are sustainable, abundant sources that have no harmful impact on the environment.

Watch How Integrity Testing Works

This test allows experts to identify cracks in your unit’s plates and assess the risk of media cross-contamination. Curious about the process? Watch the Alfa Laval explanatory animation.

Need professional advice?Would you like tailor-made advice on your heat exchanger? Fill in the online form and we will contact you at short notice.  |