How a test phase led to a rethink

At first, the Wiegert dairy in Velen, Westphalia, could hardly believe how much savings potential there is in agitators. It therefore agreed to a three-month test installation of an ALS agitator from Alfa Laval - and was convinced after a very short time.

Agitators mix ingredients, ensure a uniform consistency and stability, support the fermentation process and help to evenly distribute the product temperature in the tank. The Wiegert dairy alone has almost 40 agitators in use at its site in Velen.

This case involved a lateral agitator for homogenizing skimmed milk concentrate with a dry matter content of 35 percent. Due to its advanced age, there were repeated problems with the mechanical seals, which is why the company was looking for a replacement and contacted the Alfa Laval sales partner in Dortmund - SKS GmbH

To date, the existing agitator consumed 8.6 kilowatts of energy at full load (150 m3 ) and an operating time of around four hours per day. According to Alfa Laval's forecasts, the new agitator should reduce this consumption to less than a quarter.

|

|

"The energy results are exactly in line with Alfa Laval's calculations and forecasts."Nicolas Becker, Operations Managerat Wiegert dairy Image (front to back): Harry Petersen, SKS GmbH, Nicolas Becker, Manager Operations at Wiegert Dairy, Ralph Christoffers, Manager sustainability of Alfa Laval. |

Test results:

Same good mixing quality, significantly less power consumption

"We had difficulty believing the calculations made by Alfa Laval," explains plant manager Nicolas Becker. "After all, the old agitator had a motor with an output of 15 kilowatts, while the new agitator only has an output of 2.2 kilowatts. That made us skeptical and we were glad that Alfa Laval gave us the opportunity to see for ourselves with a test installation."The new agitator was installed within a day and was able to start work without any problems. After three months, it is clear to everyone involved that the ALS agitator delivers exactly what it promises. "The energy results are exactly in line with Alfa Laval's calculations and forecasts," says Nicolas Becker happily. "We get exactly the same good mixing quality as before, but consume significantly less electricity."

Lower operating costs and reduced CO2 emissions

Lower energy consumption reduces the dairy's operating costs by around 1,200 euros per year. At the same time, CO2 emissions are reduced by around 5.4 tons per year.The return on investment is 2.8 years. As part of its ambitious energy policy, Wiegert Milch follows the requirements of DIN EN ISO 50001, so it is obvious that the dairy has ordered a second agitator for an identical tank in addition to the test agitator already installed.

In addition, the cost- and environmentally-conscious company wants to take a close look at all existing agitators. "We didn't realize how much savings potential our agitators had."

|

|

Alfa Laval's ALS agitator is modular, energy-efficient and suitable for a wide range of tank sizes. In addition, it is suitable for applications such as CIP, sterile/aseptic and ATEX certified environments. More information |

Did you know...

With the right equipment, numerous savings can be achieved. We at SKS have experience in many other projects besides this case story. Our aim is to help you achieve your business and sustainability goals by calculating process optimisations and giving sound advice on the right choice.

Tank cleaning

30%

Water savings through the use of Alfa Laval rotary jet heads for tank cleaning

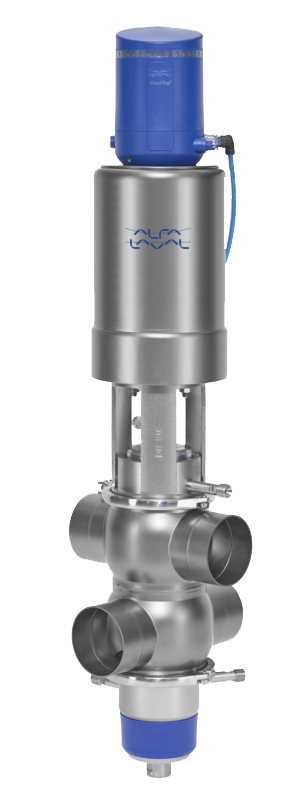

Valves

70%

Water savings with the optimized seat lift of the Alfa Laval Unique Mixproof valve

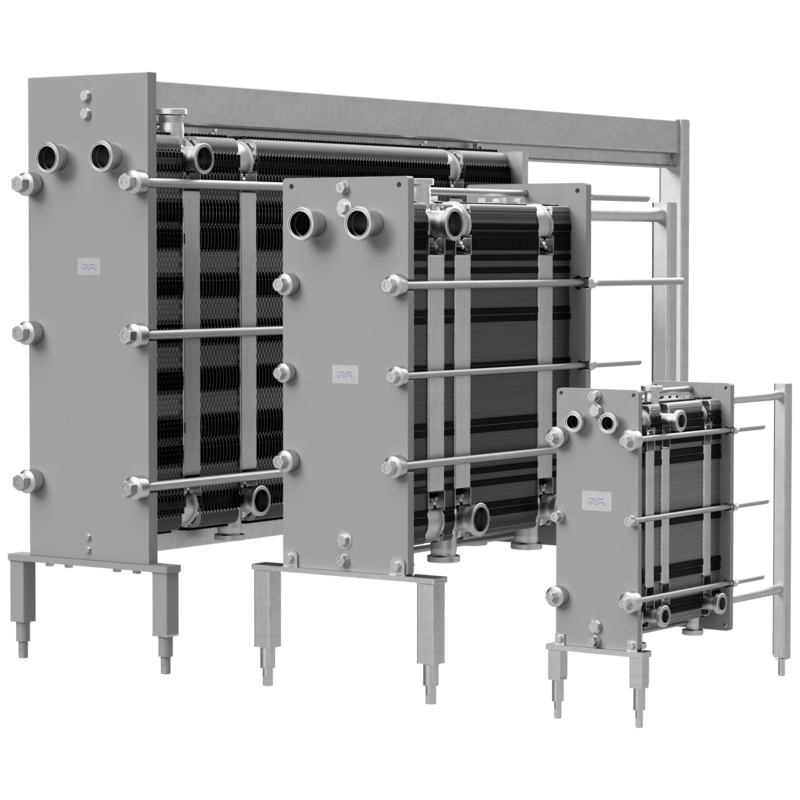

Heat Exchangers

40%

Using the right plates and design improves shear stress over the heat transfer area by up to 40%

We like to think along with you!Would you like more information or advice about Alfa Laval ALS agitators? Please complete the online form for a consultation.  |